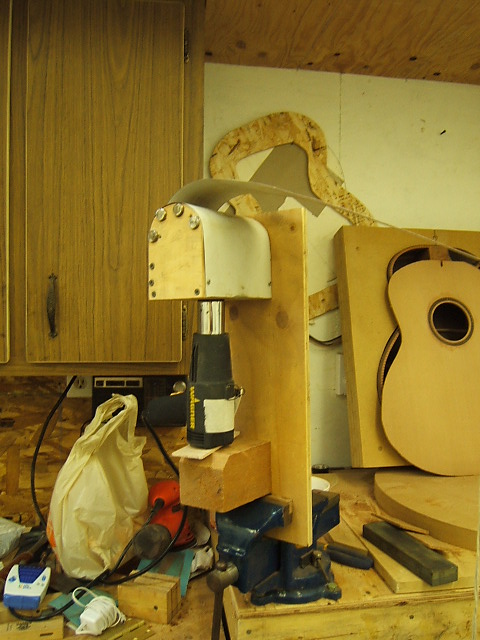

Here is my homeade one. I use a heat gun. I only use it for the sharp cutaways.

| Official Luthiers Forum! http://www-.luthiersforum.com/forum/ |

|

| Bending irons --- whadjalike? http://www-.luthiersforum.com/forum/viewtopic.php?f=10102&t=9429 |

Page 1 of 1 |

| Author: | Kelby [ Tue Nov 21, 2006 9:36 am ] |

| Post subject: | |

I use a Fox bender, but I'm just getting too darned many kinks in the cutaway area that have to be sanded out and little cracks that have to be fixed and patched. So, with Christmas coming, I'm thinking about splurging on an old-fashioned electric bending iron for those tricky areas. Whose do you like? Stew Mac's? LMI's? Others? |

|

| Author: | Michael Dale Payne [ Tue Nov 21, 2006 9:41 am ] |

| Post subject: | |

Kelby do you thin the cutout any? |

|

| Author: | John How [ Tue Nov 21, 2006 9:43 am ] |

| Post subject: | |

I think if I was to go back to using an iron, I would do what I started with. A copper pipe and a propane torch. They get hot quicker and you can learn to control the temp pretty well. You can get a couple different sizes as well. Make sure you have a good clamping system (easy to make) and put couple baffles inside the pipe. My current bender works so well though that I am hesitant to change anything. |

|

| Author: | Mike Mahar [ Tue Nov 21, 2006 9:44 am ] |

| Post subject: | |

I have the LMI and it works fine. I'd get the StewMac one though because it has that narrow extension. As soon as you have to make a mandoling or fiddle, you'll with you had it. |

|

| Author: | Kelby [ Tue Nov 21, 2006 10:43 am ] |

| Post subject: | |

Thanks, everyone! Michael, I usually thin the cutaway to about .7. I haven't had too many problems breaking, but I seem to get a fair number of "kinks." I think I'm just struggling to keep the slats tight against the wood as I lower the cutaway attachment --- I presume something is slipping around in there somewhere. |

|

| Author: | Wayne Clark [ Tue Nov 21, 2006 11:40 am ] |

| Post subject: | |

I have the LMI iron. No complaints about it. I was going to build a bender over the long weekend. Still not sure which style to go with. |

|

| Author: | arvey [ Tue Nov 21, 2006 1:07 pm ] |

| Post subject: | |

Here is my homeade one. I use a heat gun. I only use it for the sharp cutaways.

|

|

| Author: | martinedwards [ Tue Nov 21, 2006 9:18 pm ] |

| Post subject: | |

I need to make one of these soon....... aluminium pipe ok? I have a load of that handy..... I'm guessing that thick walled pipe is better to hold the heat? |

|

| Author: | Josh H [ Tue Nov 21, 2006 11:30 pm ] |

| Post subject: | |

I've been using my LMI bender for almost 3 years. It is still holding up very well. |

|

| Author: | Mark Tripp [ Wed Nov 22, 2006 12:25 am ] |

| Post subject: | |

I'm with John on this one. I use a fox bender mostly, but I use a pipe for mandos, and for touch-up on guitars. Got a piece of aluminum tube from the local machine shop for around $12. Already had a torch for home repair, made a stand from scraps of angle-iron and plywood. Total cost $12 and 20 minutes. Works great! -Mark |

|

| Author: | John How [ Wed Nov 22, 2006 12:38 am ] |

| Post subject: | |

[QUOTE=Kelby] Thanks, everyone! I think I'm just struggling to keep the slats tight against the wood as I lower the cutaway attachment --- I presume something is slipping around in there somewhere.[/QUOTE] Kelby, are you spring loading the slats against the shoe on the cutaway attachment, just like on the waist? I had considerable trouble on cutaways before I did that and it helps quite a bit. |

|

| Author: | Don Williams [ Wed Nov 22, 2006 12:55 am ] |

| Post subject: | |

[QUOTE=martinedwards] aluminium pipe ok? I have a load of that handy..... I'm guessing that thick walled pipe is better to hold the heat?[/QUOTE] Yes, Aluminum is ideal, and thicker is good, but what's also nice is to be able to have it thin enough to modify it's shape. I've never used copper pipe, but if John How says it works, I believe him! |

|

| Author: | Kelby [ Wed Nov 22, 2006 3:30 am ] |

| Post subject: | |

John, that's a great idea about spring-loading the slats. I'll have to give that a try. |

|

| Author: | John Cavanaugh [ Wed Nov 22, 2006 5:49 am ] |

| Post subject: | |

I made a bending iron from a chunk of 2 inch diameter galvanized cast iron pipe. I've been thinking about getting an electrical heating element, but I used it this weekend with a propane torch as the heat source and it worked just fine. |

|

| Author: | Bill Greene [ Wed Nov 22, 2006 5:53 am ] |

| Post subject: | |

[QUOTE=John How] [QUOTE=Kelby] Thanks, everyone! I think I'm just struggling to keep the slats tight against the wood as I lower the cutaway attachment --- I presume something is slipping around in there somewhere.[/QUOTE] Kelby, are you spring loading the slats against the shoe on the cutaway attachment, just like on the waist? I had considerable trouble on cutaways before I did that and it helps quite a bit. [/QUOTE] John, you don't have a photo of what you're talking about, do you? I'm going to start practicing bending cutaway sides soon, and was just curious. Thanks. Bill |

|

| Author: | arvey [ Wed Nov 22, 2006 11:09 am ] |

| Post subject: | |

I would highly recomend using a Heat Gun instead of a torch if you have one. Orriginally I used a torh and then tried the heat gun. Heat gun is safer and gives great control over the temp. I also found a problem with the torch blowing out sometimes. |

|

| Author: | MSpencer [ Wed Nov 22, 2006 1:42 pm ] |

| Post subject: | |

ditto on what Richard said above, my heat gun has a temp control, much safer than an open flame. I used a threaded piece of 2" oil field steel tubing with a cap. Mike |

|

| Author: | Rod True [ Wed Nov 22, 2006 1:50 pm ] |

| Post subject: | |

Wonder if the heat gun will work with the router speed control from John Hall???? I use a heat gun for my florentine cutaway bending jig and it works slick.

I also use it in a piece of 2" ss pipe I have for touch ups. |

|

| Page 1 of 1 | All times are UTC - 5 hours |

| Powered by phpBB® Forum Software © phpBB Group http://www.phpbb.com/ |

|